I have been working alone this past weeks since Chuck and Sharon have been on a road trip to Canada. Mainly, I have been making foam and fiberglass parts for the bulkhead (bulkhead51) that supports the coming and the canopy release assembly and also making panels for supporting our seatpans.

Bulkhead 51 Assembly

Here is a drawing of the assembly.

Here are some pictures of the bulkhead parts as they were being built:

Here is the 1/4″ foam core for the Foam core on top of two layers of glass.

panels laid out. Next step: adding

the fiberglass and resin.

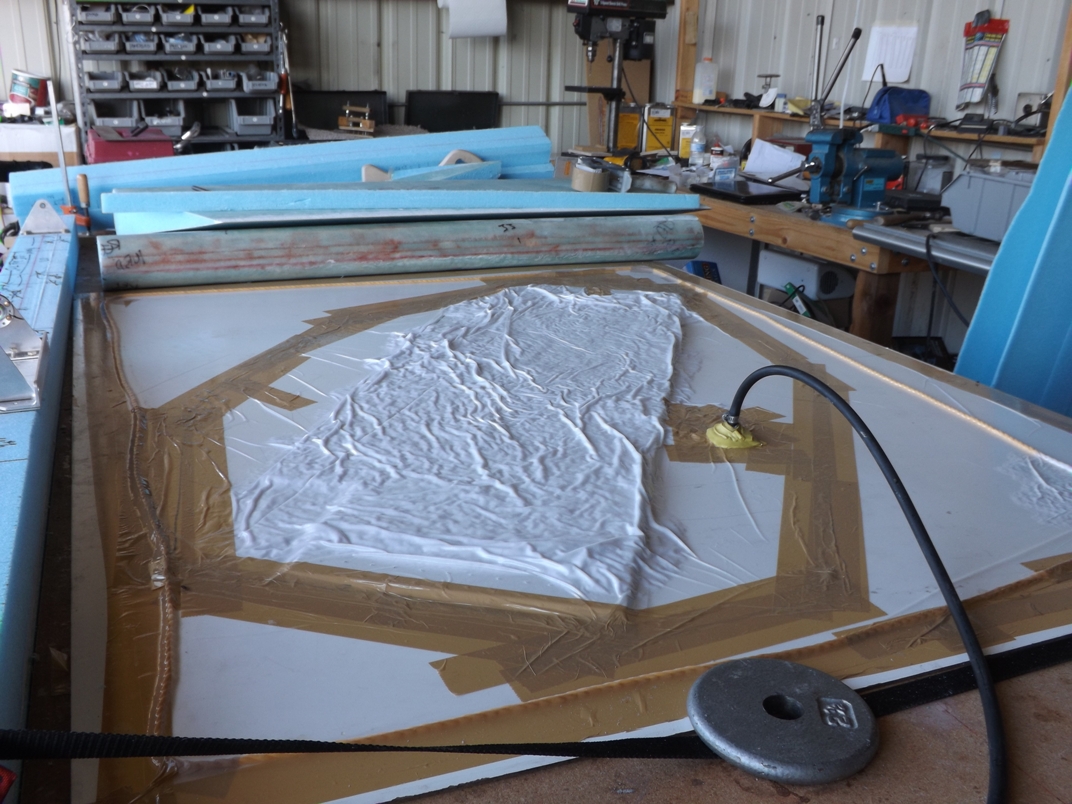

Another picture showing the vacuum Two layers of glass have been laid on

pump in the foreground. top of the foam. Ready to add release

caul and bleeder (for absorbing the

excess resin).

The lay-up is complete and vacuum The cured panel is ready to trim.

turned on.

The panels are cut out. Here is the cross bar getting its last

layer of glass.

Seat Support Panels

Here is a drawing of the seat support assembly. Below the drawing are pictures of the seat support panels being made.

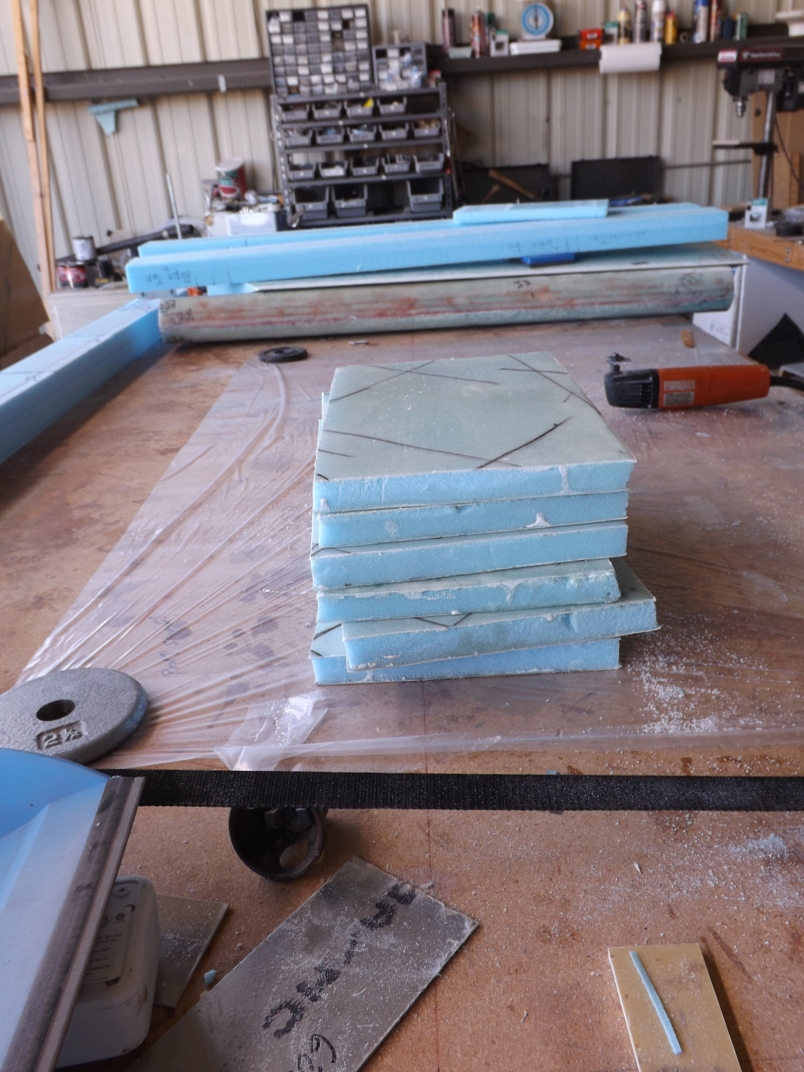

Sanding the rough cut panels The panels are getting two layers of glass

to make them 1″ thick. laid onto one side.

All panels now have 2 layers of glass on All 6 panels have been rough-trimmed.

both sides.

Four of the panels have been cut to match the drawings.

September 1, 2012: Cockpit Bulkhead 51 and Seat Supports

03 Monday Sep 2012

Posted in Uncategorized

Hi Darryl…even though I don’t understand the terminology, I do appreciate the process. I’m in awe that you’re creating a real live flying machine.

Wow, you really got some parts out. I am anxious to get the seats in. Lots to do, what to do first? It’s like making a choice in a candy store.ThanksC

Wow, you really got some parts out. I am anxious to get the seats in. Lots to do, what to do first? It’s like making a choice in a candy store.

Thanks

C